- All Articles (39)

- Battery Powered and Hand Tools (1)

- Cables and Cable Management (2)

- Case Studies (1)

- Charity Support and Activities (2)

- Company News and Updates (5)

- Enclosure Climate Control, Meters & Lighting (3)

- Enclosures (7)

- IDEC (1)

- Industrial Internet of Things - IIoT (1)

- Motor Control Components (4)

- Relays, Monitoring Relays and Timers (1)

- Schneider Electric Products (7)

- Sport Sponsorship (1)

- TLA Rail (1)

- Weidmuller (3)

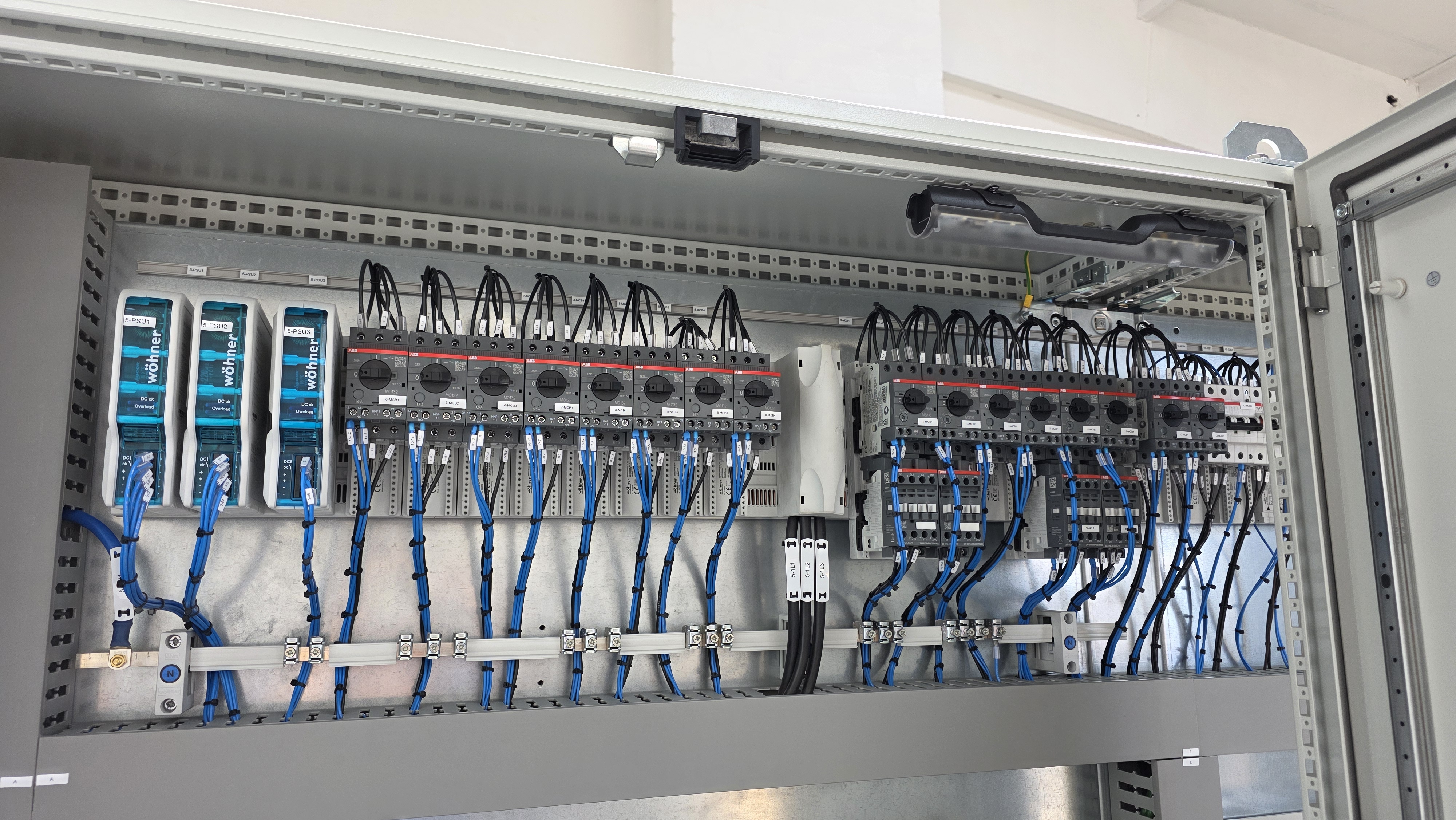

Case Study: PRH Engineering Solutions Ltd Automation and Process Control Panel

Posted on: 03/09/2025, 00:00

Good timing can make all the difference in delivering value to our customers and our recent project with PRH Engineering in Wednesbury is a perfect example.

PRH Engineering Solutions have been a TLA customer for a few years and have previously placed orders on an ad-hoc basis. However, when our Stafford branch Automation Specialist Kevin Gardner visited Phil from PRH during the early stages of a new project design, the visit opened the door to a deeper partnership.

After assessing the requirements for the build, Kevin was able to provide targeted technical recommendations for a range of automation and electrical solutions by TLA’s manufacturers, ensuring that PRH Engineering Solutions had easy access to the right products from a trusted supplier.

The Brief

The project was for a new conveyor and paint booth system for a UK based industrial gas canister company.The layout for the panel consists of:

- Load station

- Straight into the shot blast plant to clean and prepare the materials for painting

- Inspection area with a return function built in if the product is rejected and required to pass back though the shot blast

- Move onto a pre-heat oven

- Through a paint booth equipped with paint kitchen for mixing the colours required which is controlled via an intrinsically safe circuit identified by blue trunking and barriers

- Into a flash off oven which is also equipped with an inspection area and return leg on the conveyor for rejected parts

- Finally passing through the curing oven

- The product returns to the unload area for inspection and despatch

The Build

On his visit to PRH during the design phase, Kevin introduced Phil to Wöhner products and advised a busbar solution that would simplify the wiring using their crossboard with integrated power connection, component adaptors and integrated power supplies.

TLA also recommended and supplied:

- nVent Hoffman enclosures

- Pfannenberg ventilation

- ABB control gear

- WAGO terminals and electronic circuit protections

- A slimline sounder beacon

As is expected with a live project, there were design changes as the project developed. However, with our motto of “If we can, we will” and strong relationships with our manufacturers, we were able to handle these changes and urgent requirements with the help of manufacturers to minimise any delay to the project.