- All Articles (39)

- Battery Powered and Hand Tools (1)

- Cables and Cable Management (2)

- Case Studies (1)

- Charity Support and Activities (2)

- Company News and Updates (5)

- Enclosure Climate Control, Meters & Lighting (3)

- Enclosures (7)

- IDEC (1)

- Industrial Internet of Things - IIoT (1)

- Motor Control Components (4)

- Relays, Monitoring Relays and Timers (1)

- Schneider Electric Products (7)

- Sport Sponsorship (1)

- TLA Rail (1)

- Weidmuller (3)

The Complete Lug Crimping Solution from Cembre

Posted on: 11/08/2021, 10:35

Cable lugs are an engineered solution to provide the connection of power and control cables to equipment and busbars. The cost of guesswork selecting the correct lug / tool can be astronomical! Just one failed connection can result in machinery downtime (we all no the cost of this) damaged components and cable and sometimes even fires.

To achieve the very best quality crimped connection in line with the BS7609 code of practice, it is recommended to use the same manufacturer for the cable lug, tooling and die sets. The lug should be clearly marked to show the conductor size and manufacturers' name or logo.

Cembre satisfies all these requirements and with its latest generation of battery powered hydraulic crimp tools with the electronic pressure sensor, you can guarantee the precision of the crimping operation, checking the actual value of pressure and be informed of any possible errors.

Why not let TLA and Cembre help you make the correct product and tool selection?

Let’s start with the crimping tool…

Made by one of the largest European manufacturers of electrical compression connectors and related tools, the Cembre B500NDE 18V hand-held cordless hydraulic crimping tool is a very compact, extremely powerful tool, suitable for the crimping of 4mm² to 300mm² copper tube lugs.

Check out its features in this short video.

Being first of a new generation of hand-held cordless tools, the B500NDE is set apart from the competition by its ‘Bilinear’ structure, providing an ergonomic tool which reduces the torque which can be created on the user’s wrist whilst crimping.

Its features Smart Release Technology – Cembre’s new intelligent oil pressure release system, which, when selected, ceases the motor at the end of a cycle with the ram retracting automatically once the start button is released. This allows the operative to visually verify the press jaws have contacted and full compression has taken place before releasing pressure. With the New multifunction OLED display all this information is available at your fingertips, with real time data including crimping force, work cycles completed, battery charge status and even when scheduled maintenance and calibration is due.

Its features Smart Release Technology – Cembre’s new intelligent oil pressure release system, which, when selected, ceases the motor at the end of a cycle with the ram retracting automatically once the start button is released. This allows the operative to visually verify the press jaws have contacted and full compression has taken place before releasing pressure. With the New multifunction OLED display all this information is available at your fingertips, with real time data including crimping force, work cycles completed, battery charge status and even when scheduled maintenance and calibration is due.

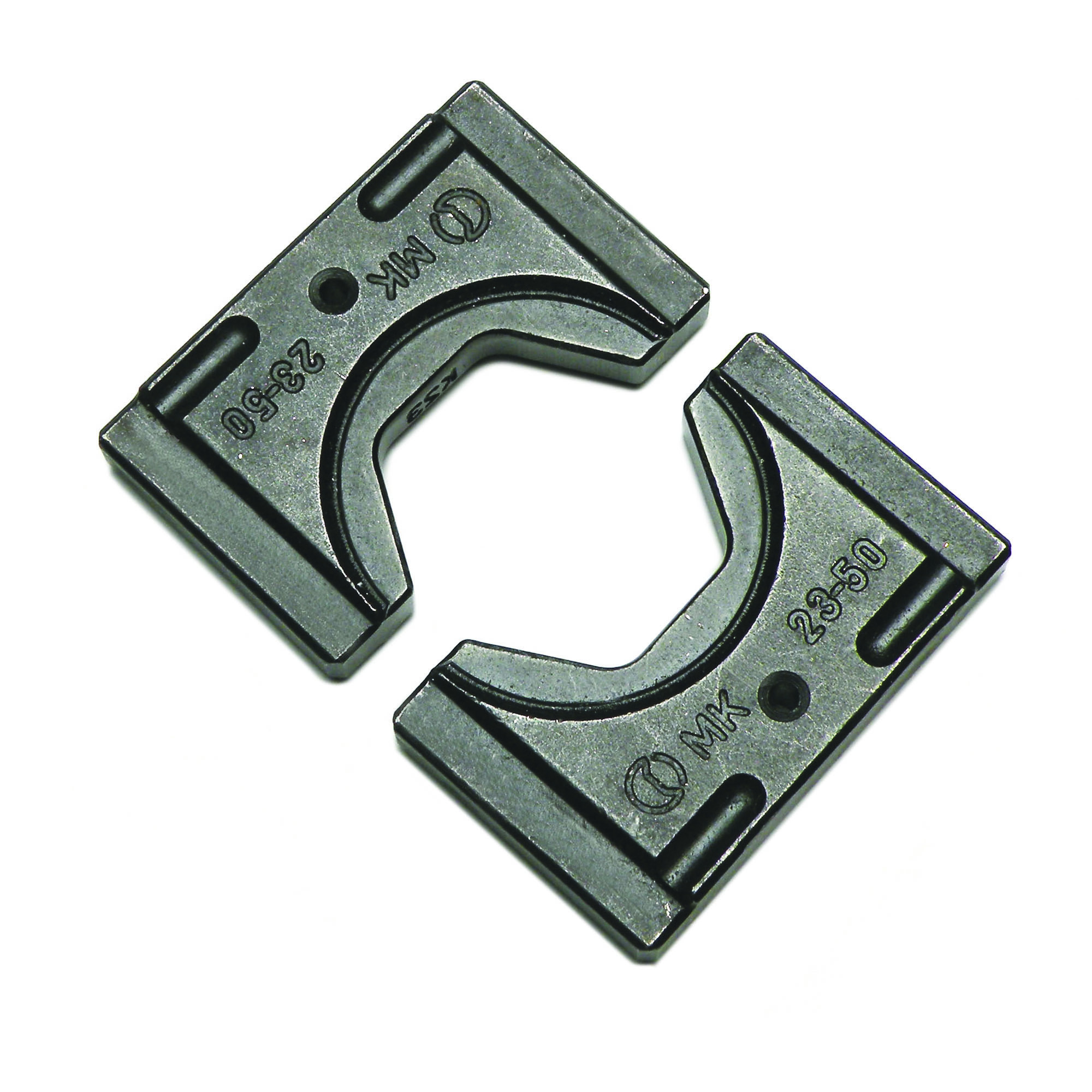

Powered with Li-Ion 18V 2Ah rechargeable high capacity batteries, the B500NDE is suitable for a wide range of connectors, from 4mm to 300mm, using the ME die sets for copper tube lugs.

More details about the B500NDE can be found here

So how about the connectors?

With extensive experience and constant innovation, Cembre Ltd has been providing high quality electrical connectors since 1986.

The A-M series is manufactured from electrolytic copper tube with dimensions designed to obtain the most efficient electrical conductivity and mechanical strength to resist vibration and pull out.

The lugs are annealed which is crucial to avoid cracking or breaking between the barrel and palm. This guarantees optimum ductility, an absolute necessity for connections to prevent severe deformation when compressed and bending of the palm during the crimping process.

Featuring an inspection hole to aid full insertion of the copper conductor, the barrel length allows easy, precise locating of the die during the crimping operation.

Cembre lugs are available in a wide range of stud sizes and palm lengths to suit your cable management needs.

Contact TLA to discuss your connector requirements - you’ll find the cost of the very best quality is surprisingly affordable…

To achieve the very best quality crimped connection in line with the BS7609 code of practice, it is recommended to use the same manufacturer for the cable lug, tooling and die sets. The lug should be clearly marked to show the conductor size and manufacturers' name or logo.

Cembre satisfies all these requirements and with its latest generation of battery powered hydraulic crimp tools with the electronic pressure sensor, you can guarantee the precision of the crimping operation, checking the actual value of pressure and be informed of any possible errors.

Why not let TLA and Cembre help you make the correct product and tool selection?

Let’s start with the crimping tool…

Made by one of the largest European manufacturers of electrical compression connectors and related tools, the Cembre B500NDE 18V hand-held cordless hydraulic crimping tool is a very compact, extremely powerful tool, suitable for the crimping of 4mm² to 300mm² copper tube lugs.

Check out its features in this short video.

Being first of a new generation of hand-held cordless tools, the B500NDE is set apart from the competition by its ‘Bilinear’ structure, providing an ergonomic tool which reduces the torque which can be created on the user’s wrist whilst crimping.

Its features Smart Release Technology – Cembre’s new intelligent oil pressure release system, which, when selected, ceases the motor at the end of a cycle with the ram retracting automatically once the start button is released. This allows the operative to visually verify the press jaws have contacted and full compression has taken place before releasing pressure. With the New multifunction OLED display all this information is available at your fingertips, with real time data including crimping force, work cycles completed, battery charge status and even when scheduled maintenance and calibration is due.

Its features Smart Release Technology – Cembre’s new intelligent oil pressure release system, which, when selected, ceases the motor at the end of a cycle with the ram retracting automatically once the start button is released. This allows the operative to visually verify the press jaws have contacted and full compression has taken place before releasing pressure. With the New multifunction OLED display all this information is available at your fingertips, with real time data including crimping force, work cycles completed, battery charge status and even when scheduled maintenance and calibration is due.

Powered with Li-Ion 18V 2Ah rechargeable high capacity batteries, the B500NDE is suitable for a wide range of connectors, from 4mm to 300mm, using the ME die sets for copper tube lugs.

More details about the B500NDE can be found here

So how about the connectors?

With extensive experience and constant innovation, Cembre Ltd has been providing high quality electrical connectors since 1986.

The A-M series is manufactured from electrolytic copper tube with dimensions designed to obtain the most efficient electrical conductivity and mechanical strength to resist vibration and pull out.

The lugs are annealed which is crucial to avoid cracking or breaking between the barrel and palm. This guarantees optimum ductility, an absolute necessity for connections to prevent severe deformation when compressed and bending of the palm during the crimping process.

Featuring an inspection hole to aid full insertion of the copper conductor, the barrel length allows easy, precise locating of the die during the crimping operation.

Cembre lugs are available in a wide range of stud sizes and palm lengths to suit your cable management needs.

Contact TLA to discuss your connector requirements - you’ll find the cost of the very best quality is surprisingly affordable…